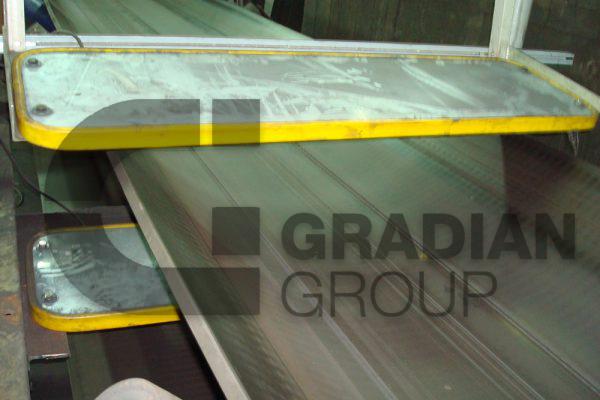

Industrial Metal Detector (for Iron Ore)

Industrial Metal Detector for Iron Ore is one of the most advanced metal detectors in the world. It is used in granulated iron ore lines, iron ore concentrate and also iron pelletizing lines.

This metal detector can distinguish and separate metal parts (ferrous and non-ferrous) from the passing material (iron ore) on the conveyor and unlike other metal detectors, it is not sensitive to iron ore passing but it is sensitive to annoying parts such as bucket teeth, parts removed from crushers and it would alarm when encountered with such material.

The technology used in the device is designed in such a way that it is not sensitive to the metal clamp of the conveyor.

Features of this device include insensitivity to ferrous minerals and granulated iron ore and concentrate, noise prevention system to prevent errors in the line stop system due to the use of wireless and mobile communications in factories, advanced design for different geographical regions, protection systems against temperature and humidity changes inside factories, ability to mark to better determine the exact location of the metal part, ability to adjust the sensitivity to determine the size of metal parts, insensitivity to the vibration of the conveyor and dust, highest global standard, possibility of making waterproof parts and insensitivity to the metal clamp of the conveyor.

Able to make waterproof parts

Advanced design for different geographical regions

Protection systems against temperature and humidity changes inside factories