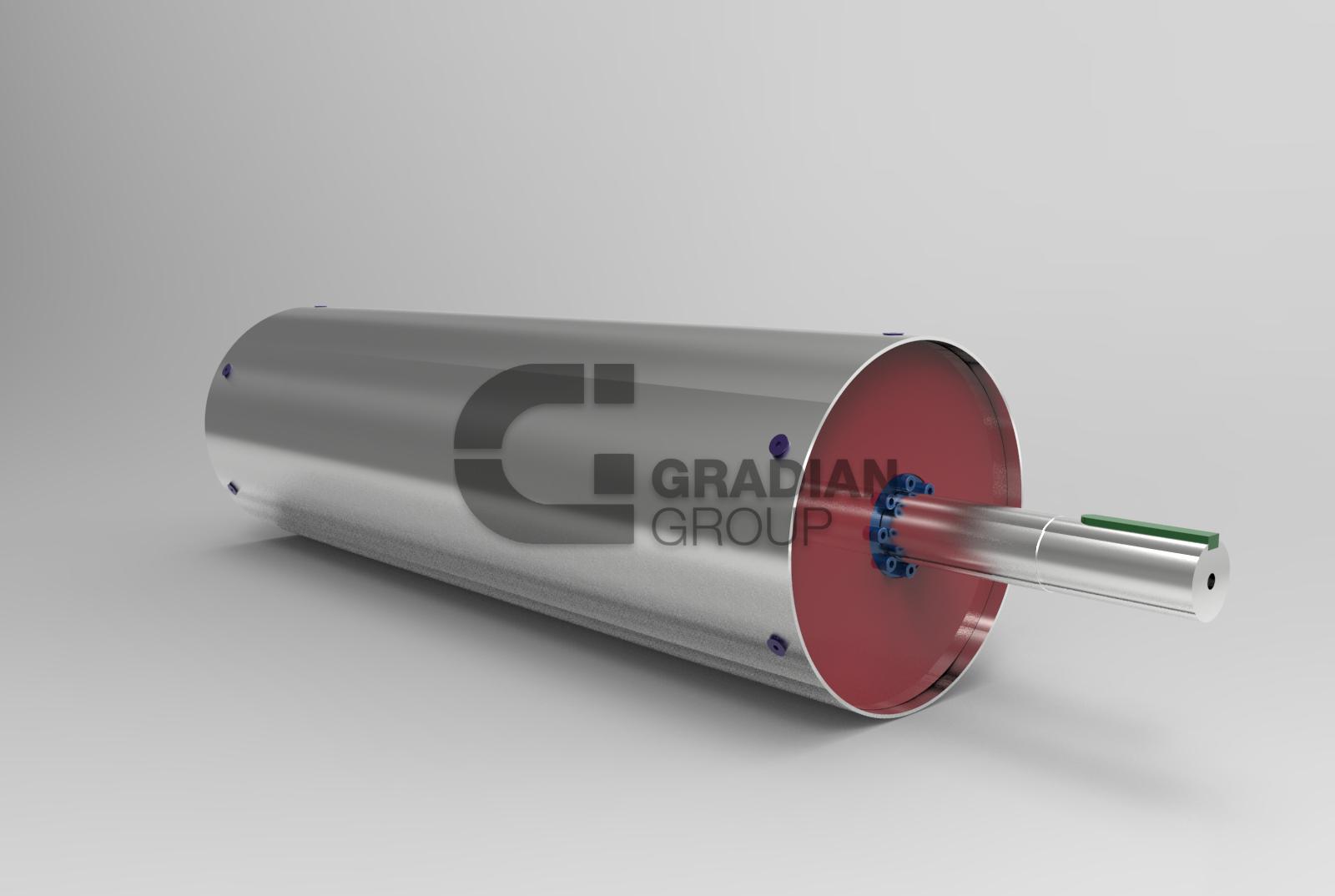

Pulley Magnet Separator

Pulley Magnet Separators are used by the conveyor belt in various industries to separate the iron parts inside the carriers. They can continuously separate iron parts and particles and automatically remove them from the production line.

This magnetic separator is one of the best ones among similar machinery on a global scale and can be designed and manufactured in two models, electric and permanent. Pulley Magnet Separator consists of a 360-degree roller with a strong magnet which functions as the drive roller of the conveyor belt. As the materials transported by the conveyor belt are in a distance from the Pulley Magnet Separator, the parts and particles are well absorbed and then transferred to the lower part of the device and separated.

One of the features of this device is the consistency and stability of the magnetic field for prolonged periods.

Separation of iron parts

Consistency and stability of the magnetic field

Can be produced in two models, electric and permanent