Permanent Magnetic Self Cleaning

One of the many causes of equipment failure in mines and industrial units is the presence of metal parts in the raw materials. They can cause damage to the crushing systems. When this happens, these systems fail, and this situation, even for a short amount of time, causes a lot of financial damage.

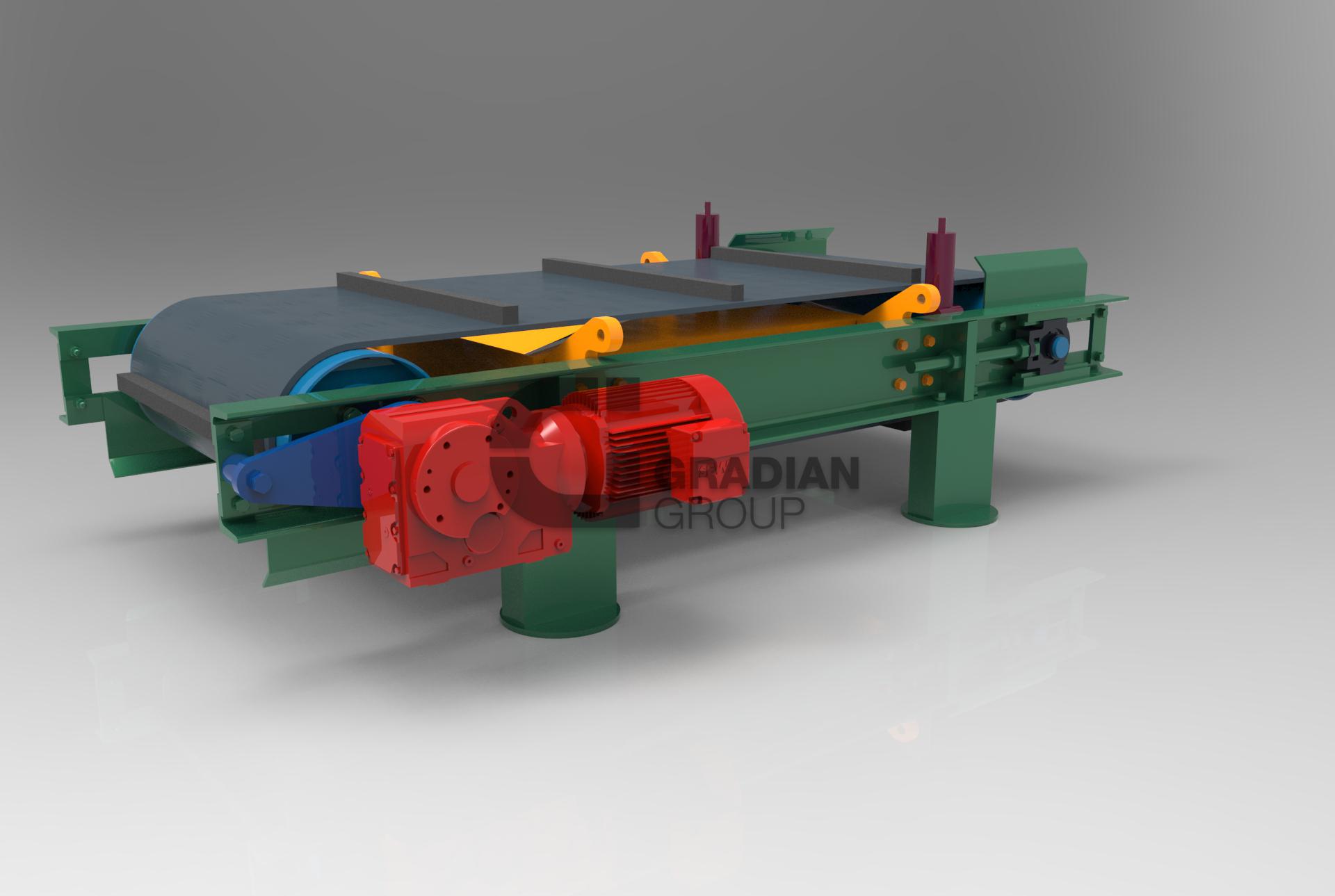

Automatic Permanent Magnetic Separator is used for separating iron parts, bucket teeth, rebars, angle bars and broken parts from chutes, screens, bolts etc. from a mixture of materials. This device is for installation in lines that have a high level of metal pollution or lacks the possibility of manual separation by the operator.

In the automatic method, the separation of the parts is done by a conveyor, the conveyor rotates around the permanent separator and throws the parts absorbed by the magnet out of the floor of the conveyor. The machine uses the power of an electric motor and gearbox to do this, and the non-magnetic angle bars mounted on the conveyor help to separate the parts.

The features of this device include the use of the strongest magnets in the world and also the design following modern standards with the highest magnetic field strength.

Designed under modern world standards

Use of the current strongest magnets in the world

Separation of iron parts, bucket teeth, rebars, angle bars, etc.