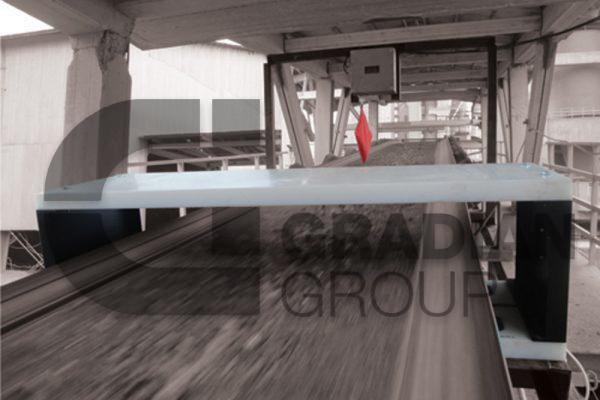

Metal Detector (for belt conveyors)

Our industrial metal detectors in the Gradian Industrial Group are among the most advanced metal detectors that can detect and separate metal parts (ferrous and non-ferrous) from the materials passing on the conveyor. In industrial, mining and steel factories, magnetic separators are used in the production line, but due to the lack of absorption of non-ferrous metals by the equipment, the damage is caused to the crushing and material transfer systems. This can be stopped by installing a metal detector on the conveyor.

Features of this device include insensitivity to ferrous minerals, noise prevention system to prevent errors in the line stop system due to the use of wireless and mobile communications in factories, advanced design for different geographical regions, protection systems against temperature and humidity changes inside factories, ability to mark to better determine the exact location of the metal part, ability to adjust the sensitivity to determine the size of metal parts, insensitivity to the vibration of the conveyor and dust, highest global standard, possibility of making waterproof parts.

Insensitivity of ferrous minerals

Separation of metal parts (ferrous and non-ferrous)

Advanced design for different geographical regions