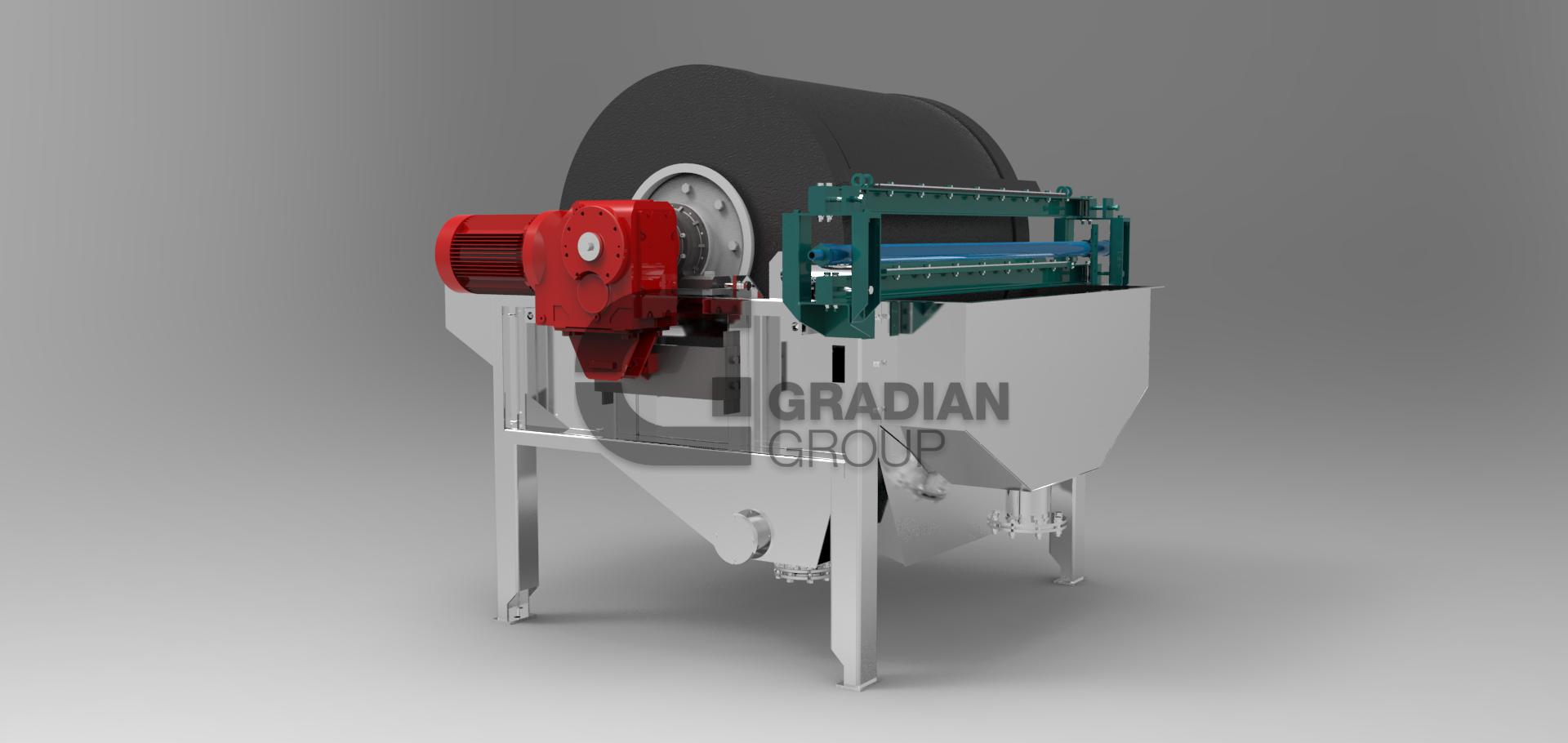

Magnetic Wet Drum Separator

Magnetic Wet Drum Separators are among the magnetic separators used in the wet and slurry paths to separate micronized iron particles from non-ferrous ones.

The wet magnetic separation of the device is done by the rotation of a stainless steel cylindrical shell around a fixed magnetic field in which the absorbed iron circulates on the separator drum shell to the last magnetic point and separates after leaving the magnetic zone.

Wet Drum Separator could be designed in three models: Low Intensity Magnetic Separator (LIMS), Medium Intensity Magnetic Separator (MIMS) and High-Intensity Magnetic Separator (HIMS).

Can be used in wet material paths and slurries

Wet magnetic separation

Separation of micronized iron particles from non-ferrous ones